|

|

| MOQ: | 1 set |

| Price: | $100,000-250,000 |

| Standard Packaging: | Sea worthy packaging |

| Delivery Period: | 90-150 days |

| Payment Method: | L/C , T/T |

| Supply Capacity: | Max 20sets per month |

Mono LDPE/PLA/PBS Roll paper 100gsm~400gsm big size Laminating machine

This machine with double shaft-less paper roll stands,suit for 3~6 inch paper core, automatic lift and easier operation. the suto splicer device realize paper in 150-300m/min speed exchange without decrease machine line speed. Ultrasonic type EPC system, makes frequent replacement materials operation more simple. Hydraulic lamination structure make coating thinner and firm. Trimming device make the finished coated paper rolls even. Special cuttion knife and rewinder design makes high speed rewinding shafts exchange possible.

Specifications:

Item: LY-ADCP-1200/1400/1700

Effective laminating width: Max:1100mm/1300mm/1600mm

Machinery speed:300m/min

Screw diameter:φ100mm/φ110mm

Max output:400kg/h

Max unwinder diameter:φ1500mm

Max rewinder diameter:φ1800mm

Laminating range:8μm~45μm

Power supplier:380V-50HZ(3phase-5wires)

PRE-TREATMENT

Compound machine

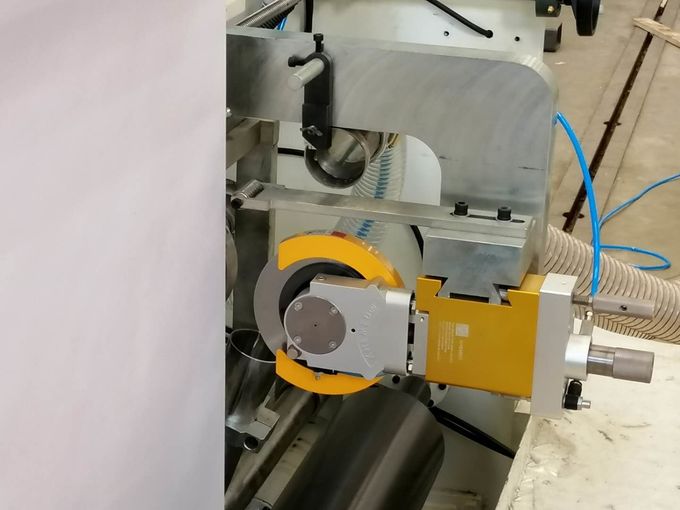

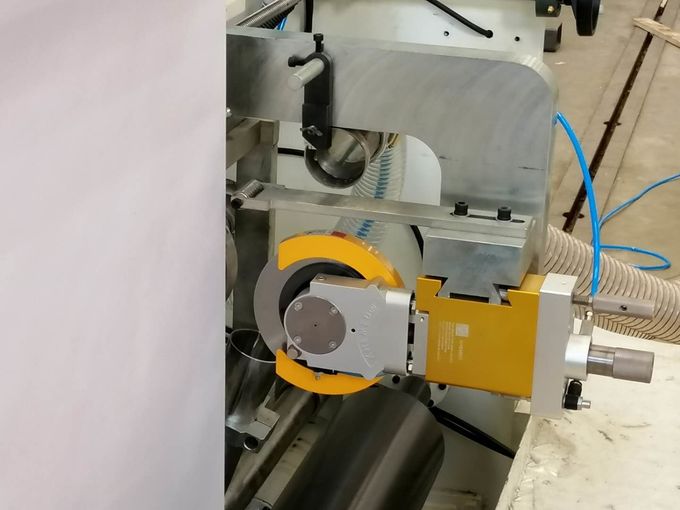

Bead cut equipment

Our Company

Jiangsu Laiyi Packing Machinery Co.,Ltd was founded in 2007 and moved to Jintan District in 2015. The new factory with enlarged scale and advanced technology has improved its brand influence and become the industry leader in the forefront of China with increasing market share in China's extrusion lamination industry.

Our Service

Enterprise Mission:

Be dedicated to be the packing machinery manufacturer who can provide the first

class machine and service to the world.

Be based on honesty to be highly valued and trusted by all interested parties and to make

contribuions o the society.

Laiyi's Values:

Constomer First

Put customer value in our first place,

to provide high-quality goods and service.

Emphasis on technique

Keep on researching core technologies and make contributions to the society.

Challenge the changes

Be dscontent to stand still and challenge all kinds of changes in the future.

people Oriented

Create corporate culture as respecting each other and making progress by learing

from each other.

Company History:

Changzhou Laiyi Plastics machinery Co.,Ltd. was established in 2007 and changed o Jiangsu Laiyi Packing

Machinery Co.,Ltd.2015. The new factory with enlarged scale and advanced technology in the new district has

iimproved its brand influence and become the industry leader in the forefront of China with a large number of market share in Chinese extrusion laminating machine industry. especially in PVDF solar energy backplane film industry, Laiyi has been in the lead in the China.

Laiyi has provided its own high quality extrusion laminating production line to customers. Laiyi has long-term strategic cooperation relationship with enterprises all over the world and is long-term cooperation supplier of Yongyi Group, Xingyuan Holding Co., Ninbo Asia Paper Co., etc in China and India Uflex Limited, Indonesia Pt. Squar Jaya., etc.

Jiangsu Laiyi has a highly sophisticated technical personnel, wiith high-quality team that can provide comprehensive and timely service to customers. "Professional qualifications to create brand" is Laiyi business objectives. " Create excellence by quality, provide service with honesty" is Laiyi's business purposes. Laiyi seeks for and improves the scientific management based on talent strategy, to face the soceity with its corporate identity as high social responsibility. in the road ahead, Jiangsu Laiyi hopes to confirm your confidence in cooperation better and realize dreams of each other faster by its fast, professional and enthusiastic service.

Our Team

Strong and flexible service capability:

from food package for snacks to liquid package for milk, from aseptic package for cosmetic and medical supplies to package for staionery and electronci products.

we produce indispensable composite films for packing industry from the commodities to the highly sophisticated products.

the extrusion laminating machine of Jiangsu Laiyi has single sided, double sided, and multi-layer co-extrusion type for various papers machinee. the high-quality and stable performance, the widely used compound films can satisfy customers' diversified demand.

| Factory Size: | 20,000-40,000 square meters | |

|---|---|---|

| Factory Location: |

NO.238 East Jinsheng Road, JinTan District, ChangZhou City, JinagSu Province,China. Post code : 213200 |

|

| No. of Production Lines: | 3 | |

| Contract Manufacturing: | OEM /ODMService Offered | |

| Annual Output Value: | US$2 Million - US$3 Million |

| Main Markets | Total Revenue (%) |

| Domestic Market | 40.00% |

| Mid East | 5.00% |

| South Asia | 5.00% |

| South America | 5.00% |

| Southern Europe | 3.00% |

| Eastern Asia | 3.00% |

| North America | 2.00% |

| Southeast Asia | 1.00% |

| Northern Europe | 1.00% |

| Eastern Europe | 1.00% |

| Oceania | 1.00% |

| Central America | 1.00% |

| Western Europe | 1.00% |

| Africa | 1.00% |

| Total Annual Revenue: | US$20 Million |

| Export Percentage: | 20% - 30% |

| Accepted Payment Currency: | USD, EUR, CNY |

| Accepted Payment Type: | T/T, L/C, Credit Card, Western Union |

| Nearest Port: | DELHI INDIA, PENANG MALAYSIA, CALLA PERU |

| No. of Employees in Trade Department: | 3-5 People |

| Average Lead Time: | 30 Day(s) |

| Export Mode: | Using an agent |

FAQ

Q: What's the size of your machine?

A: From 1200mm to 2500mm, we can design and make according to your requirement.

Q: Which machine should I choose?

A: Our extrusion laminating lines cover single side, double sides, muti-layer co-extrusion machines for roll-based paper, films, metalized films, aluminium foil, clothes, woven and non-woven fabric, etc

Q: How to carry out the machine acceptance?

A: After the installation of the machine is finished in our factory, the representive(s) of your company will be invited to inspect the test running before shipment.

Q: Does your machine have alarm devices?

A: Of course, we have warning lights in each part of our machine for paper break alarm and fault alarm.

Q: How can I install the machine?

A: Our engineers will provide service overseas after you received the shipped machine.

|

|

| MOQ: | 1 set |

| Price: | $100,000-250,000 |

| Standard Packaging: | Sea worthy packaging |

| Delivery Period: | 90-150 days |

| Payment Method: | L/C , T/T |

| Supply Capacity: | Max 20sets per month |

Mono LDPE/PLA/PBS Roll paper 100gsm~400gsm big size Laminating machine

This machine with double shaft-less paper roll stands,suit for 3~6 inch paper core, automatic lift and easier operation. the suto splicer device realize paper in 150-300m/min speed exchange without decrease machine line speed. Ultrasonic type EPC system, makes frequent replacement materials operation more simple. Hydraulic lamination structure make coating thinner and firm. Trimming device make the finished coated paper rolls even. Special cuttion knife and rewinder design makes high speed rewinding shafts exchange possible.

Specifications:

Item: LY-ADCP-1200/1400/1700

Effective laminating width: Max:1100mm/1300mm/1600mm

Machinery speed:300m/min

Screw diameter:φ100mm/φ110mm

Max output:400kg/h

Max unwinder diameter:φ1500mm

Max rewinder diameter:φ1800mm

Laminating range:8μm~45μm

Power supplier:380V-50HZ(3phase-5wires)

PRE-TREATMENT

Compound machine

Bead cut equipment

Our Company

Jiangsu Laiyi Packing Machinery Co.,Ltd was founded in 2007 and moved to Jintan District in 2015. The new factory with enlarged scale and advanced technology has improved its brand influence and become the industry leader in the forefront of China with increasing market share in China's extrusion lamination industry.

Our Service

Enterprise Mission:

Be dedicated to be the packing machinery manufacturer who can provide the first

class machine and service to the world.

Be based on honesty to be highly valued and trusted by all interested parties and to make

contribuions o the society.

Laiyi's Values:

Constomer First

Put customer value in our first place,

to provide high-quality goods and service.

Emphasis on technique

Keep on researching core technologies and make contributions to the society.

Challenge the changes

Be dscontent to stand still and challenge all kinds of changes in the future.

people Oriented

Create corporate culture as respecting each other and making progress by learing

from each other.

Company History:

Changzhou Laiyi Plastics machinery Co.,Ltd. was established in 2007 and changed o Jiangsu Laiyi Packing

Machinery Co.,Ltd.2015. The new factory with enlarged scale and advanced technology in the new district has

iimproved its brand influence and become the industry leader in the forefront of China with a large number of market share in Chinese extrusion laminating machine industry. especially in PVDF solar energy backplane film industry, Laiyi has been in the lead in the China.

Laiyi has provided its own high quality extrusion laminating production line to customers. Laiyi has long-term strategic cooperation relationship with enterprises all over the world and is long-term cooperation supplier of Yongyi Group, Xingyuan Holding Co., Ninbo Asia Paper Co., etc in China and India Uflex Limited, Indonesia Pt. Squar Jaya., etc.

Jiangsu Laiyi has a highly sophisticated technical personnel, wiith high-quality team that can provide comprehensive and timely service to customers. "Professional qualifications to create brand" is Laiyi business objectives. " Create excellence by quality, provide service with honesty" is Laiyi's business purposes. Laiyi seeks for and improves the scientific management based on talent strategy, to face the soceity with its corporate identity as high social responsibility. in the road ahead, Jiangsu Laiyi hopes to confirm your confidence in cooperation better and realize dreams of each other faster by its fast, professional and enthusiastic service.

Our Team

Strong and flexible service capability:

from food package for snacks to liquid package for milk, from aseptic package for cosmetic and medical supplies to package for staionery and electronci products.

we produce indispensable composite films for packing industry from the commodities to the highly sophisticated products.

the extrusion laminating machine of Jiangsu Laiyi has single sided, double sided, and multi-layer co-extrusion type for various papers machinee. the high-quality and stable performance, the widely used compound films can satisfy customers' diversified demand.

| Factory Size: | 20,000-40,000 square meters | |

|---|---|---|

| Factory Location: |

NO.238 East Jinsheng Road, JinTan District, ChangZhou City, JinagSu Province,China. Post code : 213200 |

|

| No. of Production Lines: | 3 | |

| Contract Manufacturing: | OEM /ODMService Offered | |

| Annual Output Value: | US$2 Million - US$3 Million |

| Main Markets | Total Revenue (%) |

| Domestic Market | 40.00% |

| Mid East | 5.00% |

| South Asia | 5.00% |

| South America | 5.00% |

| Southern Europe | 3.00% |

| Eastern Asia | 3.00% |

| North America | 2.00% |

| Southeast Asia | 1.00% |

| Northern Europe | 1.00% |

| Eastern Europe | 1.00% |

| Oceania | 1.00% |

| Central America | 1.00% |

| Western Europe | 1.00% |

| Africa | 1.00% |

| Total Annual Revenue: | US$20 Million |

| Export Percentage: | 20% - 30% |

| Accepted Payment Currency: | USD, EUR, CNY |

| Accepted Payment Type: | T/T, L/C, Credit Card, Western Union |

| Nearest Port: | DELHI INDIA, PENANG MALAYSIA, CALLA PERU |

| No. of Employees in Trade Department: | 3-5 People |

| Average Lead Time: | 30 Day(s) |

| Export Mode: | Using an agent |

FAQ

Q: What's the size of your machine?

A: From 1200mm to 2500mm, we can design and make according to your requirement.

Q: Which machine should I choose?

A: Our extrusion laminating lines cover single side, double sides, muti-layer co-extrusion machines for roll-based paper, films, metalized films, aluminium foil, clothes, woven and non-woven fabric, etc

Q: How to carry out the machine acceptance?

A: After the installation of the machine is finished in our factory, the representive(s) of your company will be invited to inspect the test running before shipment.

Q: Does your machine have alarm devices?

A: Of course, we have warning lights in each part of our machine for paper break alarm and fault alarm.

Q: How can I install the machine?

A: Our engineers will provide service overseas after you received the shipped machine.